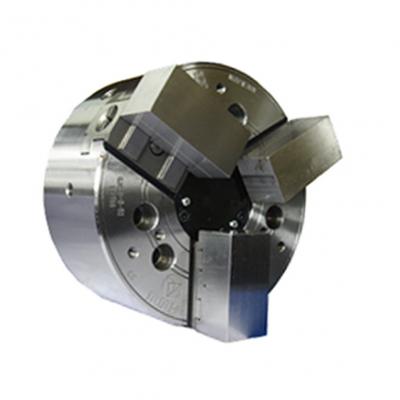

MMK Matsumoto has designed many different types of specialty chucks.

Depending on your specific type of application and/or size, shape, and weight of your workpiece, can offer to design and build a custom chuck.

Examples:

- Want to avoid the troubles of cutting chips or shorten maintenance time? Sealed Chucks

- Need to reduce labor time during setup changes? SMED System, U‐Chuck, K‐Chuck

- Need a chuck specifically for mounting onto a machining center table? Stationary Chuck(STC), RS6J

- Looking for small‐sized, power operated chucks? USS Chuck

- Need a special chuck for a non‐round or irregular sized part? Multi‐Jaw Chuck, 2‐Jaw Chuck

MMk can design and build you a custom chuck, to meet the needs of your specific application. Please consult with an application specialist to discuss your requirements